A World Made Possible with PVDF

- Light Link™ SLA resin allows Kynar® PVDF to crosslink in UV light, producing parts rivaling injection-molded quality using low-cost equipment.

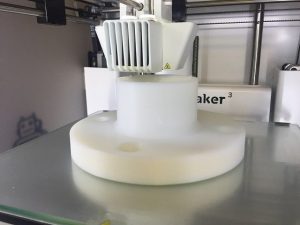

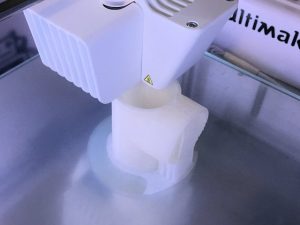

- We extrude our Fluorinar™ PVDF filaments for fused deposition modeling (FDM). Our PVDF filaments allow 3D printing of parts for high-purity and aggressive chemical applications and are available in copolymer, black, static dissipation and homopolymer options.

- Strong-Ty® PVDF cable ties are an excellent choice for applications that require chemical or UV resistance, radiological sterilization or high-purity performance.

- Our USP Class VI Purisan™ mixers are ideal for demanding applications in the pharmaceutical and chemical process industries.

- Beautiful Kryptonar™ PVDF coatings provide corrosion-resistant surfaces for diverse chemical environments.