Strong-Ty™ PVDF Cable Ties: long-term UV resistance made possible by Kynar®

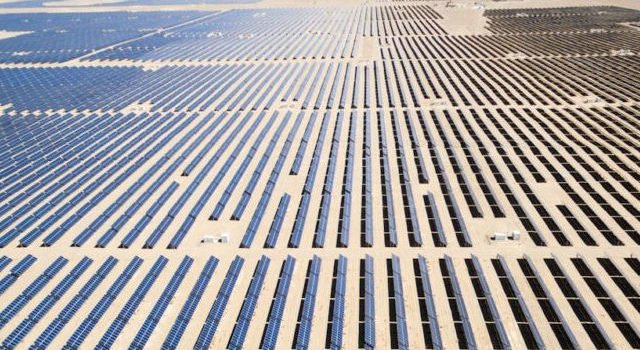

Photovoltaic (PV) arrays have a 25-year plus life expectancy. However, the nylon and polyethylene cable ties can fail in a matter of months due to combinations of UV, temperature extremes, zinc chloride corrosion and high humidity. Commodity cable ties provide no dependable long-term solution for wire and cable management in PV arrays. The reality of a commodity cable tie failure makes system-wide inspections a constant requirement in order to prevent ground fault failures.

Fortunately, there is a better choice for long-term wire and cable management in PV applications.

Strong-Ty™ PVDF ties represent a better choice for PV wire and cable management. Accelerated UV exposure under a Xenon arc for 5000 hours in addition to sunlight exposure testing in Florida shows no change in mechanical or chemical properties in several varieties of the Kynar® copolymers. This data was recently presented by Arkema at the 2017 National Renewable Energy Laboratory (NREL) PV Reliability Workshop. A portion of this presentation is available here.

Based on simple calculations, UV radiation should not provide sufficient energy to break the chemical bonds found in most commodity plastics such as polyethylene and nylon. However, embrittlement and loss of tensile strength occur in these materials after UV exposure and are the result of chemical impurities or structural defects along the polymer backbone. These molecular irregularities absorb energy and initiate polymer degradation. Kynar® PVDF shows no effect or change after long-term UV exposure.

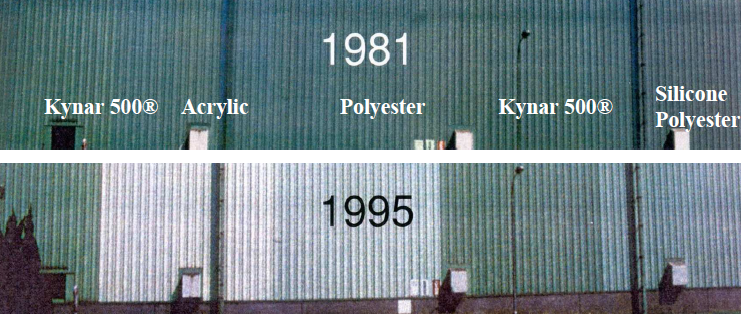

An example of PVDF performance under relentless UV exposure is the PVDF coating system used by Metal Sales for their roof panel systems. They offer a 35-year warranty of the Kynar® 500 coating against color fade and chalking. Changes in color and loss of surface material are results of UV exposure exhibited in other polymers. Metal Sales offers a longer 45-year warranty on the PVDF coating against blistering, cracking and peeling. This same company only provides a 25-year warranty on the steel substrate against rupture, perforation or structural failure. More confidence in the PVDF coating than in the steel substrate!

Strong-Ty™ PVDF cable ties are made from 100% Kynar® and provide the maximum UV resistant service life for outdoor wire and cable management in PV applications. Available in a natural color, Strong-Ty™ cable ties do not require the addition of carbon black or UV inhibitors to provide long-term dependable outdoor performance.

Additional information about Strong-Ty™ PVDF Cable Ties and PVDF, in general, can be found on the following pages:

Strong-Ty™ Cable Tie TDS

Strong-Ty™ Cable Tie Engineering Drawing

Kynar® Chemical Resistance Chart

Accelerated Weathering of Kynar® PVDF – A Case For Better PV Cable Ties

Product Overview

Regulatory Compliance

Chemical Resistance

Sterilization

UV Resistance